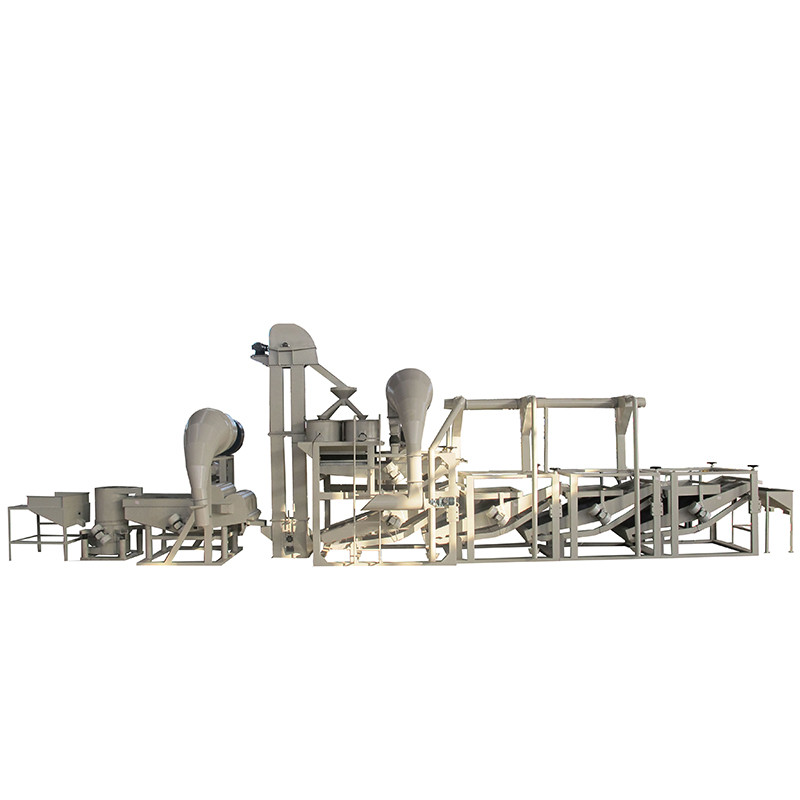

Common Sunflower Kernel Hulling Machine

Introduction of sunflower kernel hulling machine:

Here, sunflower kernel hulling machine refers to the shelling machine remove the seeds shell with a high efficiency. It contains 4 national patents and is an advanced technology in China. It can be used to separate the various sunflower kernel hulling especially pernicious impurities in sunflower kernels. Besides, the percentage of the broken kernels is adjustable, therefore it is an optimum hulling equipment for sunflower kernels. It has the features of easy operation and maintenance and good cleaning effect.

Sunflower kernel hulling machine mainly consists of input hopper, 4 sets of circular-motion and vibrating cleaners to remove heavy debris with similar size and weight properties, vibrating suction cleaner, metal remover, laminated screen, 2 sets of combined spiral elevators and the electric control cabinet.

Sunflower kernel hulling machine technological process:

Feeding →elevating→ cleaning broken kernels and heavy debris with similar size and weight properties for the 1st time→ cleaning heavy debris with similar size and weight properties for the 2nd time→elevating →cleaning small impurities, light impurities and metals→finished products

Technical parameters:

Power:10.34kw (380v 3 phase 50Hz)

Input capacity: 0.8-1mts/hour (varies with raw materials)

% of impurities after cleaning: 0.1% max.( free of hair, stones, glass and metals)

% of broken kernels:3-10% adjustable according to requirement (broken kernel is less than 1/2 of the whole kernel).

Space occupied:8.8m×5.5m

Height: 3.4m

Weight: 5.2mts

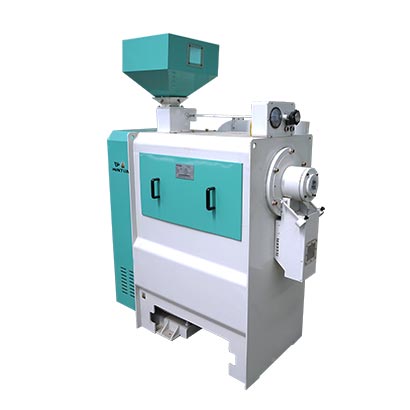

1 Ton/hour Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete

Malaysia 1Ton/Hour Lentil Peeling Plant Installation

1 Ton/Hour Lentil Peeling Plant was installed successfully in Malaysia.