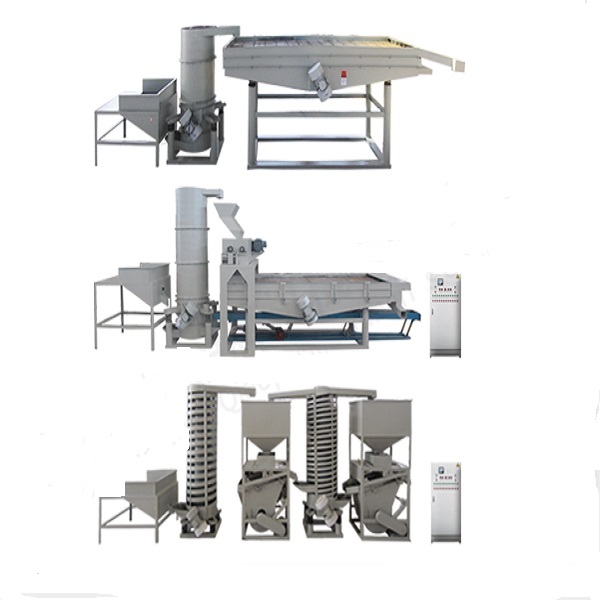

WT Series Pumpkin Seeds Hulling Machine

The pumpkin seeds hulling machine is a very important invention in our company and pumpkin seeds hulling machine not only can hull, dust, clean, but also of metering and packing. The hulling machine can improve the efficiency of seed hull for production.

The seed hulling machine is a horizontal placement of the conveying pipe, in succession to the pipe end of the hair dryer, in succession to the conveying pipe on the other end of the crash box, seed in impact box and between the hair dryer is conveying pipe at the middle of the input pipe, hit the box have a and by the hair dryer blowing into the air driven seed movement direction perpendicular to the wall impingement. And thus seed collision to hit the wall and seeds from the impinging wal Bounce back collide with each l other in to order achieve the purpose of dehulled seeds.

Pumpkin seeds hulling machine features:

1. It adopts wet method to shell pumpkin seeds.

2. It has higher shelling rate and less broken rate compared with the old type.

3. It adopts recycling shelling method.

4. It uses negative selection method in husk collection instead of blowing method and reduces dust.

5. It increases the separation and sieving size and makes the kernels separated completely.

6. It has compact structure and low energy consumption.

Technical parameter of pumpkin shelling machine:

Power: 8.19kw(380v)

% of whole kerenls:95% min. (kernels that are less than 1/2 whole kernels are brokens)

% of inshell in final kernels: 2% maximum

Input capacity: 200-300kgs/hour

Space occupied: 6.5m×2.9m

Height:3.5m

Weight:2.5mt

20 Corn and Grain Peeling Machines Equipped with Diesel Engines Shipped to Kenya

20 Corn and Grain Peeling Machines Equipped with Diesel Generators Successfully Loaded and Shipped to Kenya.

Vietnam 6Tons/Hour PeaS Cleaning and Peeling Line Successfully Shipped

On April 10, 2025, the 6-ton/hour peas cleaning and peeling production line ordered by a Vietnamese client was successfu

20T Lentil Peeling and Splitting Production Line Delivered to Ethiopia

China Win Tone Machinery devotes itself to the research and development of grain processing equipment and complete sets